Navigation offcanvas

- Basic Guide

- Getting Started

- Interface

- Options Menu

- Robot Programs

- Robot Manufacturing

- Tips and Tricks

- Smaller/Larger References (-/+)

- Rename Object (F2)

- Show/Hide Robot Workspace (*)

- Open your last project or file (Ctrl+1)

- Show the Station Tree as a side window

- Show or Hide Objects (F7)

- Show or Hide the text on the screen (/)

- Move Reference Frames or Objects (Alt)

- Move a Robot Tool (Alt+Shift)

- Reorder Items in the Tree

- Reorder Items in the Tree without moving them

- Change the size of the Station Tree

- Teach a Robot Target (Ctrl+T)

- Modify a Robot Target (F3)

- Teach Robot Targets on a Surface

- Move Robot Targets on a Surface (Alt+Shift)

- Change the Robot Configuration

- Check the status of a Robot Program (F5)

- Faster Simulation (hold Spacebar)

- Generate a Robot Program (F6)

- Export a Simulation (Ctrl+E)

- Send a Program to the Robot (Ctrl+F6)

- Run the Program on the Robot

- Display the Robot Trace (Alt+T)

- General Tips

- Add-ins

- Add-ins

- File Manager

- Palletizing

- Computer Vision

- Display Panel

- OPC-UA

- Realistic Robot Simulation (RRS)

- Components Add-In

- Augmented Reality

- Welding Add-In

- RoboDK CNC

- IO Monitor Plugin

- Blender Export Add-in

- Plugins for CAD/CAM

- RoboDK Add-Ins for CAD/CAM Software

- RoboDK Plugin for BobCAD-CAM

- RoboDK Plugin for FeatureCAM

- RoboDK Add-In for Fusion 360

- RoboDK Plugin for hyperMILL

- RoboDK Add-In for Inventor

- RoboDK Plugin for Mastercam

- RoboDK Plugin for MecSoft

- RoboDK Add-In for Onshape

- RoboDK Add-In for Rhino

- RoboDK Add-In for Siemens Solid Edge

- RoboDK Add-In for SolidWorks

- Collision Detection

- Examples

- Robot Tips

- ABB robots

- Brooks robots

- Comau robots

- Denso robots

- Fanuc robots

- Han’s robots

- Hanwha robots

- JAKA robots

- KEBA Controllers

- KUKA robots

- Mecademic

- Yaskawa Motoman robots

- Omron-TM Robots

- Universal Robots

- Post Processors

- Virtual Reality

- RoboDK API

- Robot Drivers

- Accuracy

- RoboDK TwinTool

- RoboDK TwinTrack

- Robot Calibration (Laser Tracker)

- Robot Calibration (Optical CMM)

- Robot ballbar testing

- ISO9283 Performance Testing

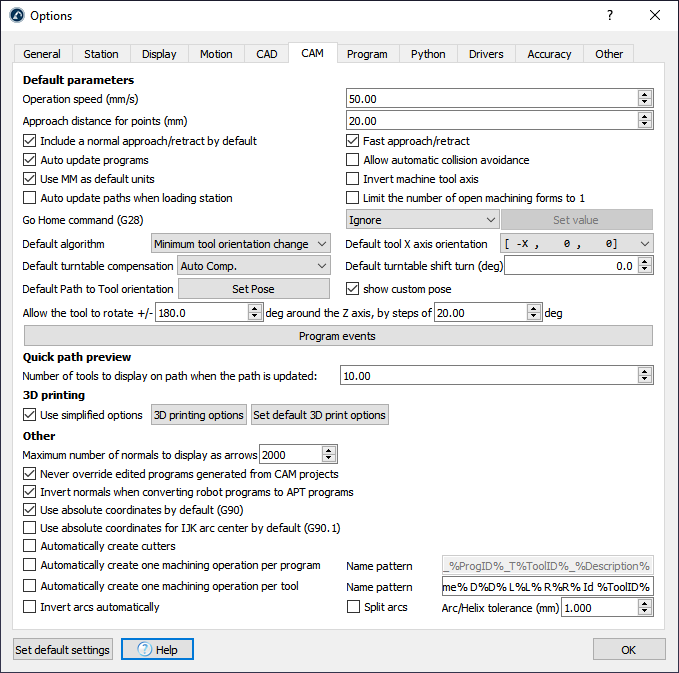

The CAM section (computer-aided manufacturing) shows all the settings related to robot manufacturing operations, such as robot machining or 3D printing, and how to import robot toolpaths created using CAM software.

The Operation speed is the default speed used in operations for curve and point follow projects. The curve/point follow project is available in the Utilities menu.

The Approach distance for points is the default distance used to approach to points in a point follow project. This option is useful for applications like drilling or spot welding.

Include a normal approach/retract by default will include a 100 mm normal approach to the toolpath.

It is possible to ignore the Go Home command (G28 ISO code) set by some robot machining programs or set it to a specific value (XYZ coordinates).

The Program events defines what actions are taken for specific G-code events, such as setting digital outputs, managing extruder heads or triggering specific programs at different stages of the manufacturing operation.

Other options are available to define the default settings when a new robot machining project is started. These are the same settings available from the robot machining menu.

The Quick path preview section allows setting how many tools are displayed as a preview when moving the reference frame or the tool frame of a manufacturing operation.

It is possible to open the 3D printing options of the Slicer from the 3D printing section. A Slicer splits an object into a machine toolpath, then, the toolpath can be easily converted to a robot program with RoboDK.

Robot programs generated from CAM programs can be modified after they have been generated. However, updating the settings from the robot machining menu will override any previously generated program. Check Never override edited programs generated from CAM projects to avoid losing any changes.

The Length of the displayed path normals (mm) is the length of the white vector representing the normal of the CAM toolpath. The CAM toolpath is displayed in green.